Case Study: From Storage Crisis to 5-Star Service—How JR Hammer and Business Partner Lecky’s Solved This Agribusiness Company’s Complex Cable Waste

When Australia’s agricultural sector generates substantial cable waste, traditional disposal methods often can’t keep up. A leading integrated pork producer discovered this firsthand when a major infrastructure upgrade created more cable waste than their usual systems could manage.

Their partnership with Lecky’s and JR Hammer through the RecyCable™ program shows how the right approach can transform waste management from a logistical nightmare into a streamlined operation.

The Challenge: Existing Disposal Methods Reach Their Limits

As part of a leading Australian agribusiness company, this agricultural operation runs extensive facilities across New South Wales and Victoria, focusing on breeding, growing, and processing pigs as part of a fully integrated operation. With multiple piggeries and processing facilities, their operations naturally generate large volumes of mixed cable waste and electric motors.

The Pile-Up: When Small Problems Compound

The company’s Electrical Supervisor & Process Electrician explains the challenges they faced with their previous disposal approach:

Space constraints

Cable waste was consuming valuable operational space in their workshop, which had limited square footage. Every square meter of storage mattered in their facility.

Logistics nightmares

The real pain point was collection reliability. Getting trucks to arrive for scrap metal collection became a persistent issue. Even when trucks arrived, timing created bottlenecks when trying to swap full bins for empty ones on site.

Limited traceability

Their local contractor arrangement provided no documentation of recycling processes. For a company with strong ESG commitments, this lack of documentation was problematic.

Volume limitations

Their existing approach simply wasn’t designed for scale. Previous cable disposal volumes were significantly smaller than what eventually went to JR Hammer.

When Timing Creates Opportunity: Major Upgrades Mean Major Waste

The situation intensified when the company embarked on significant infrastructure improvements. The major motor control changeover, combined with silo demolition projects, created substantial volumes of contaminated materials that traditional recyclers couldn’t handle effectively.

JR Hammer benefited from the timing of this large infrastructure upgrade, which generated:

- Over 1.2 tonnes of contaminated copper buzz bar

- Over 500 kg of aluminium cables

- Over 600 kg of XLPE materials

- Over 300 kg of small cables

- Electric motors requiring specialised processing

The Solution: RecyCable™ Program Implementation

In May 2025, the agribusiness company partnered with Lecky’s and JR Hammer through the RecyCable™ program. This triangular relationship created a seamless solution that addressed every pain point.

The Three-Way Win: How Simple Partnerships Solve Complex Problems

Simplified process: JR Hammer provides reusable 2 cubic meter bins (6×4, 1 tonne capacity) that are collected every couple of months, perfectly matching the company’s waste generation cycle while offering superior storage compared to IBCs.

Advanced Processing: At JR Hammer’s Melbourne facility, contaminated materials and electric motors undergo specialised processing using cutting-edge European machinery and new technology currently being developed through R&D partnerships with CSIRO and RMIT University.

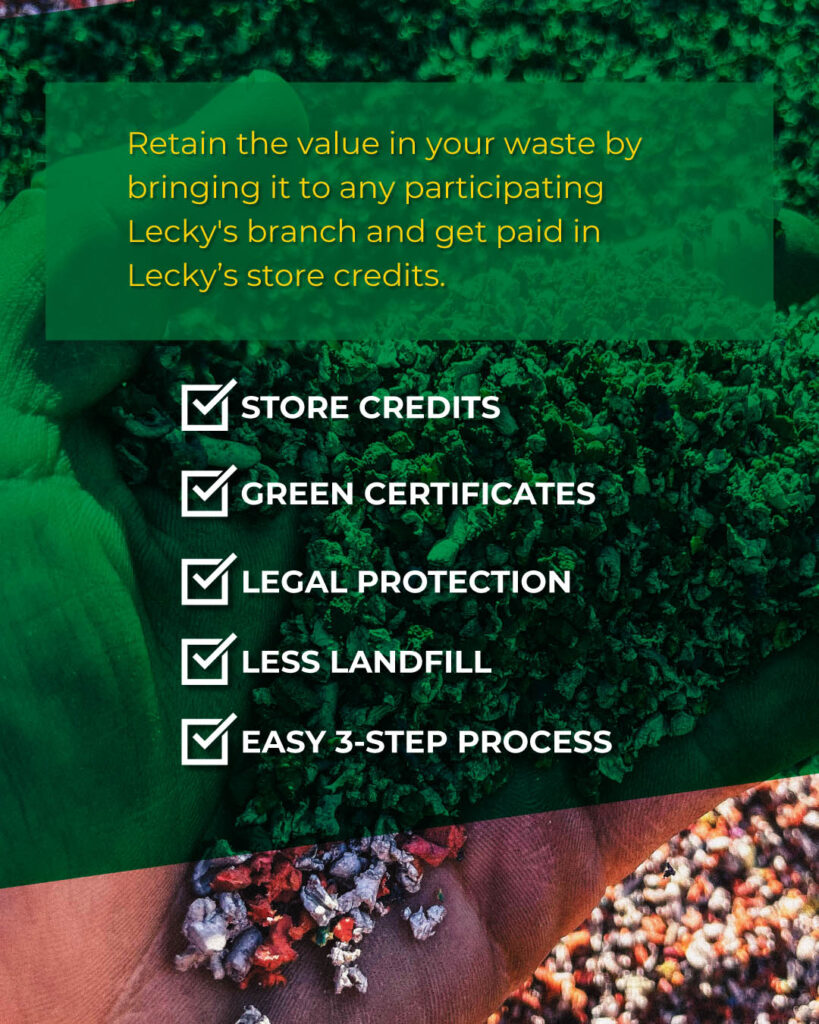

Value Recovery: Processed materials generate store credits through Lecky’s branch system, calculated by metal content/type × weight, creating tangible returns from waste streams.

Complete Documentation: JR Hammer issues sustainability certificates and provides detailed reporting, supporting the agribusiness company’s ESG requirements with full traceability.

When Advanced Tech Meets Real-World Waste

JR Hammer’s investment in advanced processing technology enables exceptional recovery rates. Where traditional recyclers achieve around 50% recovery, JR Hammer consistently delivers a minimum 92% recovery across all material types, nearly double the industry standard.

This means more of the company’s waste materials return to the circular economy as valuable resources rather than ending up in landfill.

The partnership delivered immediate operational improvements that the company’s electrical team could feel daily:

Space Recovery

The solution freed up valuable workshop space for productive activities and became available for operational use again, providing significant real estate value within their facility.

Reliability You Can Count On

Scheduled service collections happened exactly as promised and became a cornerstone of the ongoing partnership, with JR Hammer consistently delivering on their commitments.

Service Flexibility

JR Hammer showed flexibility by adjusting bin supply based on waste volume, providing single or multiple bins as needed to match changing operational demands.

Seamless Partnership

Lecky’s were able to facilitate most of the interaction, creating a smooth experience with minimal administrative burden.

The complete service approach, including pickup, eliminated the complexity that had previously characterised their waste management. “It was easy. Made it very easy for us,” notes the company’s electrical supervisor about the transformation.

The swift pickup service and proactive communication made waste management predictable and hassle-free. The on-site bin solution provides ongoing convenience for future waste management needs.

Sustainability Goals: From Policy to Practice

For this agribusiness company, ESG performance isn’t optional but integral to their operations. The company has comprehensive environmental targets supported by dedicated environmental departments operating nationally and globally.

The JR Hammer partnership directly supports these objectives by:

- Providing comprehensive documentation and traceability

- Achieving a minimum 92% material recovery rates

- Offering sustainability certificates for ESG reporting

- Supporting circular economy principles through advanced processing

The partnership actively helps the company achieve their sustainability commitments.

The 5-Star Reality Check

When asked to rate JR Hammer’s service and partnership, the electrical supervisor’s response is clear: “5 out of 5” and confirmed they were “happy” with the service quality.

The service quality and results speak for themselves, earning the client’s agreement to vouch for the partnership’s value.

Breaking Down 2+ Tonnes: Where Every Kilo Counts

JR Hammer’s specialised processing capabilities handled the agricultural company’s complex waste stream with impressive results:

Material Recovery:

- 1.2+ tonnes of contaminated copper buzz bar processed

- 500+ kg of aluminium cables recovered

- 600+ kg of XLPE materials processed

- 300+ kg of small cables recycled

- Electric motors successfully dismantled and separated

Recovery Rate

92% across all material types, demonstrating the power of advanced processing technology over traditional methods.

Value Generation

Regular credit earnings through Lecky’s branch system provide tangible returns calculated by metal content and weight.

Why This Matters Beyond the Agri-operations Team

The agri-production business’ partnership with JR Hammer represents forward-thinking leadership in agricultural sustainability. By choosing advanced recycling solutions over traditional disposal methods, they demonstrate that environmental responsibility and worksite efficiency can align perfectly.

The success stems from several key factors:

Technology Leadership

92% recovery rates through advanced processing capabilities

Service Excellence

Complete pickup service eliminates operational complexity

Strategic Partnership

The triangular relationship with Lecky’s creates seamless delivery

Value Creation

Store credits transform waste costs into financial returns

Sustainability Impact

Measurable environmental benefits support business ESG goals

What This Australian Farming Business’ Success Means for Your Operation

The agricultural sector faces increasing pressure to meet sustainability targets while maintaining streamlined workflow. The company’s experience with JR Hammer proves that the right partnership can deliver both environmental impact and commercial value.

For agribusinesses dealing with substantial cable waste, electric motors, and mixed materials, this case study demonstrates the potential for:

- Significant space recovery in operational facilities

- Reliable, flexible collection services

- Advanced processing that maximises material recovery

- Full documentation by issuing sustainability certificates to support ESG reporting

- Partnership models that simplify rather than complicate operations

The client’s experience encapsulates the transformation: from storage headaches and unreliable collection to a streamlined system that made operations significantly easier.

If this agricultural firm’s story sounds familiar, JR Hammer’s RecyCable™ program might be the solution your operation needs.

With partnerships across leading electrical wholesalers and advanced processing technology, we make it easy to unlock the full value of your waste while supporting your sustainability goals.