Behind Recycling Certificates: What Actually Happens to Your Waste After Collection?

A recycling certificate is more than just a badge of honour in environmental responsibility. It plays a crucial role in the traceability of a company’s sustainable efforts, offering proof that a certain percentage of recycled materials are verified through third-party certification processes like GreenStar or ISO 14001.

This traceability matters because it creates accountability in the recycling chain by allowing companies to prove their sustainability claims meet the proper environmental regulations and offer visibility into the entire lifecycle of their product. This also removes the threats of greenwashing by replacing vague, unsubstantiated claims with verifiable, data-backed results.

While many Australian businesses in the building and industrial sectors would proudly showcase these green certificates as part of their environmental efforts, it’s also worth asking the inconvenient truth: what happens to your cable and PVC waste after it’s been collected?

The uncomfortable truth is that most of these certificates are awarded without any proper verification set in place as to what happens to your waste after it’s been collected.

What normally happens is that you submit your waste and receive a piece of paper claiming it was 100% recycled (even confidently checking the ESG compliance box), but in reality, significant volumes still end up in landfill.

The smoke and mirrors of recycling certification

“The recycling industry is unfortunately full of smoke and mirrors with significant greenwashing,” says Josh, Founder of JR Hammer, who’s witnessed this gap in accountability firsthand. There’s no tracking, verification, nor sense of accountability.

This growing gap between what’s documented on paper versus what happens behind the scenes has long been a concern in Australia’s recycling ecosystem. Both KPMG and the Australian Industry Group (AIG) have cited poor downstream transparency as a key issue.

Research conducted by the Vinyl Council for Australia also confirms that only 3-5% of PVC is recycled in the country annually.

Green Star’s verification blind spot

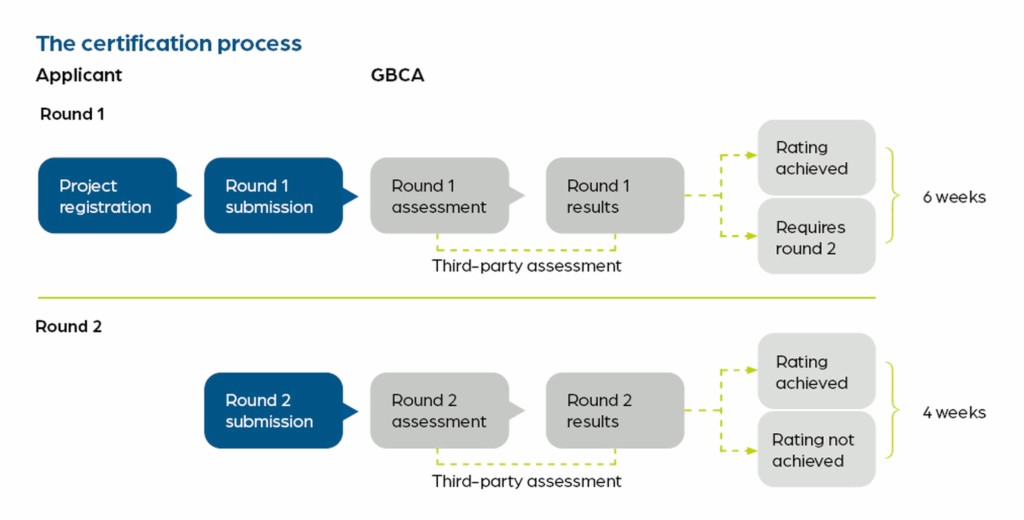

Green Star—a trusted sustainability rating tool for companies—requires builders and contractors to nominate a recycler for their waste, but there’s no verification process to even check the actual recycle outcomes. Anyone can complete the ESG paperwork without checking if it ended up in landfill.

When Josh pushed one major recycling company on their claims, “they finally admitted they were landfilling the material.” This false sense of compliance is a systemic issue often disguised as greenwashing. It’s important to ask these critical questions before your next waste collection to avoid potential liability:

- Do your recycling partners disclose how much percentage of your waste is being recycled and what ends up in landfill?

- What are their downstream processes, and do they disclose it?

- Do they provide evidence and trace your materials from collection to final reuse?

- Is their data auditable, transparent, and independently verified?

Genuine recyclers welcome these questions. Questionable ones will avoid them.

Source: new.gbca.org.au/green-star/certification-process/

What is the smart business case for real recycling?

It would mean having high material recovery rates, a genuine ESG compliance that can withstand audits, and claims and data backed with credible partnerships to protect your business from greenwashing risks.

Scrap the old ways and rethink waste: transparency as the standard

The circular economy is all about honest, traceable waste recovery.

At JR Hammer, our approach is built on verifiable outcomes, seen in our very own RecyCable™ program:

- 90% verified recycling rate for cables (compared to industry standard’s 50%)

- R&D partnerships with CSIRO and RMIT to enhance PVC recovery

- Verified memberships with the Vinyl Council of Australia and Australian Cable Initiative

- Full supply chain traceability with downstream processor credentials

Every tonne of cable waste that ends up in landfill under the guise of greenwashing, regardless of any sustainability claims made about its disposal, is both an environmental damage and economic waste.

When companies claim one thing in their recycling process but not truly practice accountability, it highlights their lack of transparency and signals that sustainability isn’t being taken seriously across the industry.

This is where traceability becomes crucial. Being able to trace recycled content builds brand credibility and trust not only with customers but with stakeholders and regulators, as well, and can become a competitive advantage in a landscape where environmental responsibility is no longer optional but expected.

This is why our approach goes beyond greenwashing. We’re not just at the forefront of solving the PVC recycling challenge, we deliver real results backed by partnerships and technology to prove it.

Ready to get real about recycling?

When it comes to our certificates you know exactly what you’re getting. We are transparent with how much is recycled and at what rate.

For further information about recycling certificates, please reach out via our contact form.

Contact JR Hammer for transparent recycling solutions that deliver verified results, not just certificates. Download our capability statement or request a waste audit consultation today.