Case Study: From Cable Waste to Revolutionary Concrete – How Recycled PVC Cable is Powering Sustainable Construction

In Australia’s growing push toward sustainable development in the construction industry, capturing and retaining the value of materials such as cables is essential to forming a more sustainable industry.

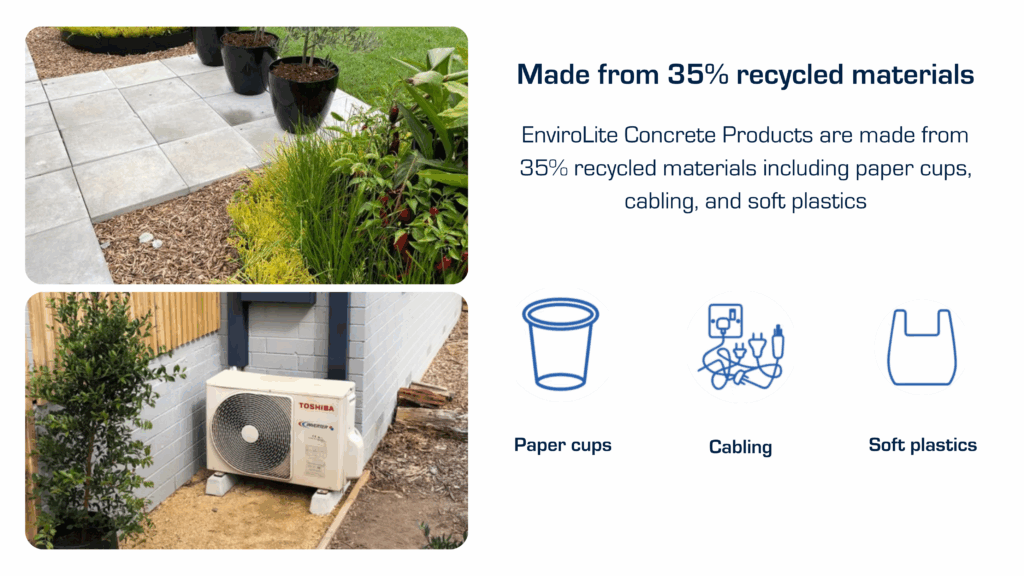

Our recent collaboration with Gully Concrete, manufacturer of Envirolite®, which is a lightweight and eco-friendly concrete building material, proves just that.

At the forefront of this innovative partnership is our shared commitment to the circular economy, always finding ways to recover cable and industry ‘waste’ into durable, recycled materials for consumer-based products.

The challenge: Turning waste into opportunity

JR Hammer specialises in diverting post-industrial PVC cable waste from landfill and transforms it into clean, reusable raw materials. Leveraging European processing machinery and proprietary technologies to process cable PVCs, it provides the precise specifications for the material needed to manufacture Evirolite®.

By incorporating recycled PVCs into the Envirolite® range, it produced a sustainable yet high-performance concrete product that weighs half of the standard alternatives used in the construction industry. It’s used in everything from prefabricated panels, floor underlays, and civil engineering projects.

Expertly engineered for sustainable manufacturing

Part of what makes Envirolite® innovative is its ability to incorporate lightweight additives like recycled PVC instead of high-carbon materials like virgin fillers and expanded polystyrene. Integrating recycled materials into core building products manufactured is a major step toward sustainable construction practices.

To ensure quality and consistency, we apply strict quality control that ensures the PVCs used in the Envirolite® range are clean, stable and production ready. This consistency has been key to producing a high-quality, eco-conscious concrete blocks that meet compliance and environmental standards.

This partnership is a model for how the construction industry can champion principles in sustainability with real-life application of the circular economy:

- Material Recovery: JR Hammer recovers usable PVC from industrial cable waste and makes them a reliable supply chain of consistent, high-quality materials

- Product Integration: Gully Concrete integrates recycled PVC into concrete, creating the revolutionary Envirolite® product containing 35% recycled content with high structural integrity

- Environmental Benefit: Results in less waste, fewer use of virgin materials, and a greener construction and manufacturing footprint

Why this matters

A recent study suggests Australia could generate 100,000 tonnes of solar panel and plastic-based waste by 2035, with the construction and manufacturing sectors being among the country’s largest users of resources and producers of carbon emissions.

By collaborating with JR Hammer, Gully Concrete has been able to reduce raw material extraction, help in lowering carbon footprint in its Envirolite® products, support industrial-scale waste recovery, and create value from materials that were once considered landfill. This partnership also delivers additional advantages:

- Builders and contractors: Envirolite® products weigh 50% less than traditional concrete making it easier to transport and install, therefore reducing labour costs and workplace injuries

- For both business: Enhanced ESG credentials, commercial success of Envirolite® products that are now available in various sizes for diverse applications, and savings on material costs through recycling process

Want to be part of the solution?

At JR Hammer, we’re always looking to work with manufacturers, builders, and innovators who share our vision of turning cable waste into valuable resources.

If you’re developing products that could benefit from high-quality recycled PVC or want to discuss circular recovery solutions for your business, let’s work together.

Visit jrhammer.com.au/what-we-do/ to learn more.