Case study: How RecyCable Solved G-Star Services’ Workshop Headache to a Seamless Recycling Solution

“It gets picked up each week, free’s up space and to find out everything is recycled is good for the environment. It’s a good initiative and a win-win for everyone.” Tim Gleeson, G-Star Services

G-Star Services’ had a problem the team didn’t fully realise needed solving. The Tullamarine-based electrical and refrigeration business handles everything from domestic installs to commercial maintenance and new builds – which means cable waste is constant.

A trailer blocking the workshop’s main walkway had become a daily frustration. Cables had to be manually loaded, space was tight, and workflow suffered. But at least the waste was being recycled… or so the team thought.

The Challenge

G-Star Services’ workshop faced a common trade dilemma: limited space and a static recycling solution that didn’t fit the operation.

The trailer sat in the main walkway – a constant obstacle in a high-traffic area. Every time cable waste needed clearing, someone had to manually haul it onto the trailer. Time-consuming, physically demanding, and an OH&S concern waiting to happen.

Like most electrical contractors, G-Star Services assumed sending cables to scrap meant proper recycling. Whole cables went into bins headed for the scrap yard (for the copper value) and the PVC conduit ends up in general waste, likely destined for landfill. But here’s what many don’t realise: even at the scrap yard, traditional processors only extract the metals. The PVC insulation wrapped around each cable? Stripped away and discarded.

That means approximately half of every cable becomes waste – a knowledge gap that’s common across the electrical industry, largely because cable recycling best practices aren’t taught during trade apprenticeships.

The Solution: When a Wholesaler Spots the Problem First

Ken, Business Development Manager at Lecky’s , recognised that G-Star Services’ waste management wasn’t working. The existing arrangement caused difficult collections, impacting daily operations.

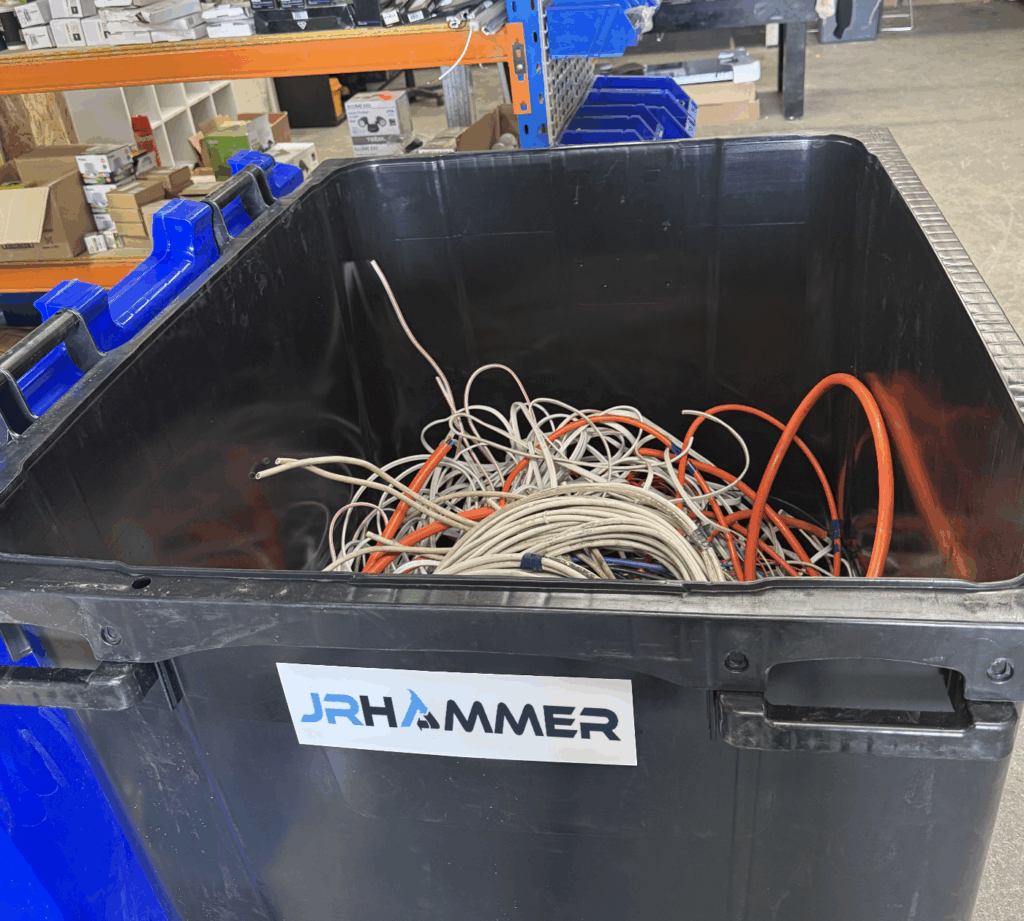

Ken connected G-Star Services with JR Hammer’s RecyCable™ program – a cable recycling initiative designed specifically for electrical contractors and delivered through wholesaler partnerships like Lecky’s.

The solution was straightforward: wheelie bins with drop-tail gate lifters. No trailer blocking walkways. No manual hauling of heavy cables – just drop them in the bin, and when it’s full, the lift mechanism handles the work. G-Star Services started with one bin, then added a second as the system proved its value.

The key was the partnership model. G-Star Services didn’t need to manage a new vendor relationship. Collections, credits, and communication all flowed through the existing Lecky’s account – the same people the team already dealt with for supplies.

Since the Switch

Workshop flow: The trailer’s gone. The main walkway isn’t blocked anymore, and the workshop functions efficiently.

Manual handling: Eliminated. No more lifting heavy cables onto trailers – the bin’s lift mechanism does the work.

Flexibility: Mobile bins move where they’re needed. When work shifts to different areas of the workshop, waste management moves with it.

Predictable collections: Regular two-week pickup cycle by JR Hammer provides predictable waste management with no surprises.

Genuine recycling: Not just copper recovery – the PVC gets properly processed, too. JR Hammer’s mechanical separation technology recovers over 90% of cable materials (compared to the industry standard 50%), and both metals and plastics return to manufacturing supply chains rather than landfill.

Admin simplicity: Recycling credits flow directly into G-Star Services’ Lecky’s account. One relationship, one system, simplified paperwork.

RecyCable Model’s Three-way Win

The bins solve the immediate problem, but the partnership model makes it sustainable long-term.

For contractors like G-Star Services: waste management that fits operations rather than disrupting them. No new vendors to manage, credits processed directly, and genuine and transparent sustainability outcomes.

For wholesalers like Lecky’s: another way to add value for customers and strengthen relationships. Ken identified and solved a problem the G-Star Services team didn’t fully recognise they had.

For the circular economy: cable waste that was previously half-recycled now gets properly processed, keeping materials in the supply chain instead of landfill.

About RecyCable™: JR Hammer’s sustainable cable recycling program delivered through partnerships with electrical wholesalers including Lecky’s and Middy’s, connecting electrical contractors with advanced recycling technology while providing store credits and competitive financial returns.

Want the same result G-Star Services achieved? Contact your electrical wholesaler about RecyCable, or get in touch with us at admin@jrhammer.com.au or 1300 574 267.